Circular News

This feels like a movement

For years, circularity sat in the background; a word for conferences, a slide in sustainability decks. But lately, it’s begun to feel different. Real. Tangible. Less theory, more traction.

You can sense it in the conversations…

Manufacturers like iGuzzini , Reggiani Illuminazione and Linea Light Group are rethinking what happens to products at the end of their first life. Some are opening stockrooms and donating slow-moving luminaires through initiatives such as Donate-A-Light rather than writing them off. Others, like Whitecroft Lighting , are actively building reuse into their business models, designing for repair, refurbishment, and redeployment from the start.

At the same time, initiatives such as Material Index and Finishes and Interiors Sector are creating the digital infrastructure to matchmake between donors and recipients, making reuse both practical and trackable.

Clients are moving too. The Crown Estate is now prioritising circular procurement over linear replacement, treating lighting not as a consumable, but as an asset to be retained, reused, and redeployed.

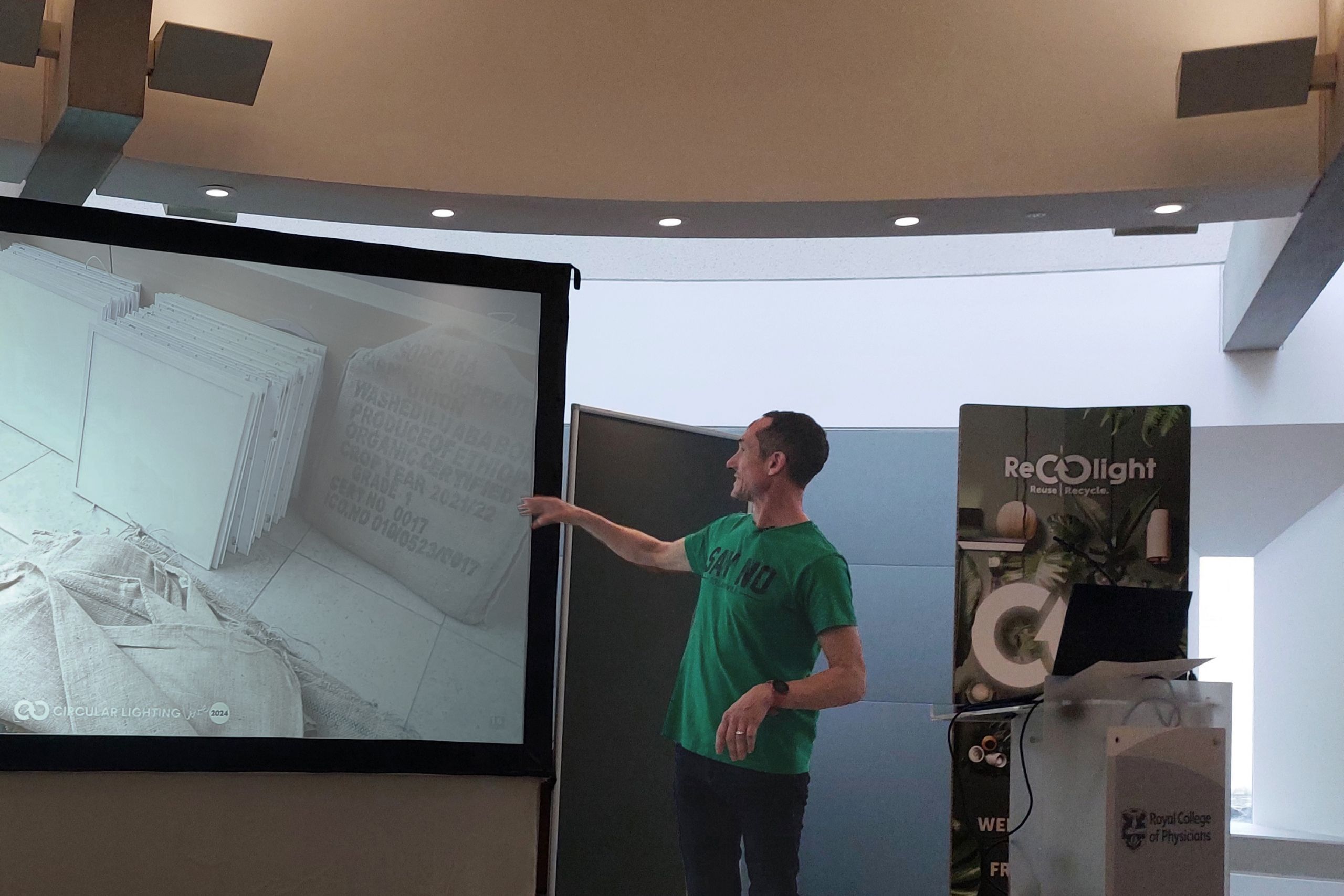

Architects like Orms , engineers such as Hoare Lea , and industry voices including Ray Moloney and Recolight are all pulling in the same direction. Add to that the UK Green Building Council (UKGBC) , whose advocacy is helping turn circularity from a niche idea into mainstream policy. The sense of alignment across the sector is unmistakable. And that’s just what we are seeing within lighting.

Across the wider construction industry, we’re beginning to confront the absurdity of what we throw away. Perfectly good materials, fittings, and finishes, skipped and replaced simply because it’s easier than reusing them.

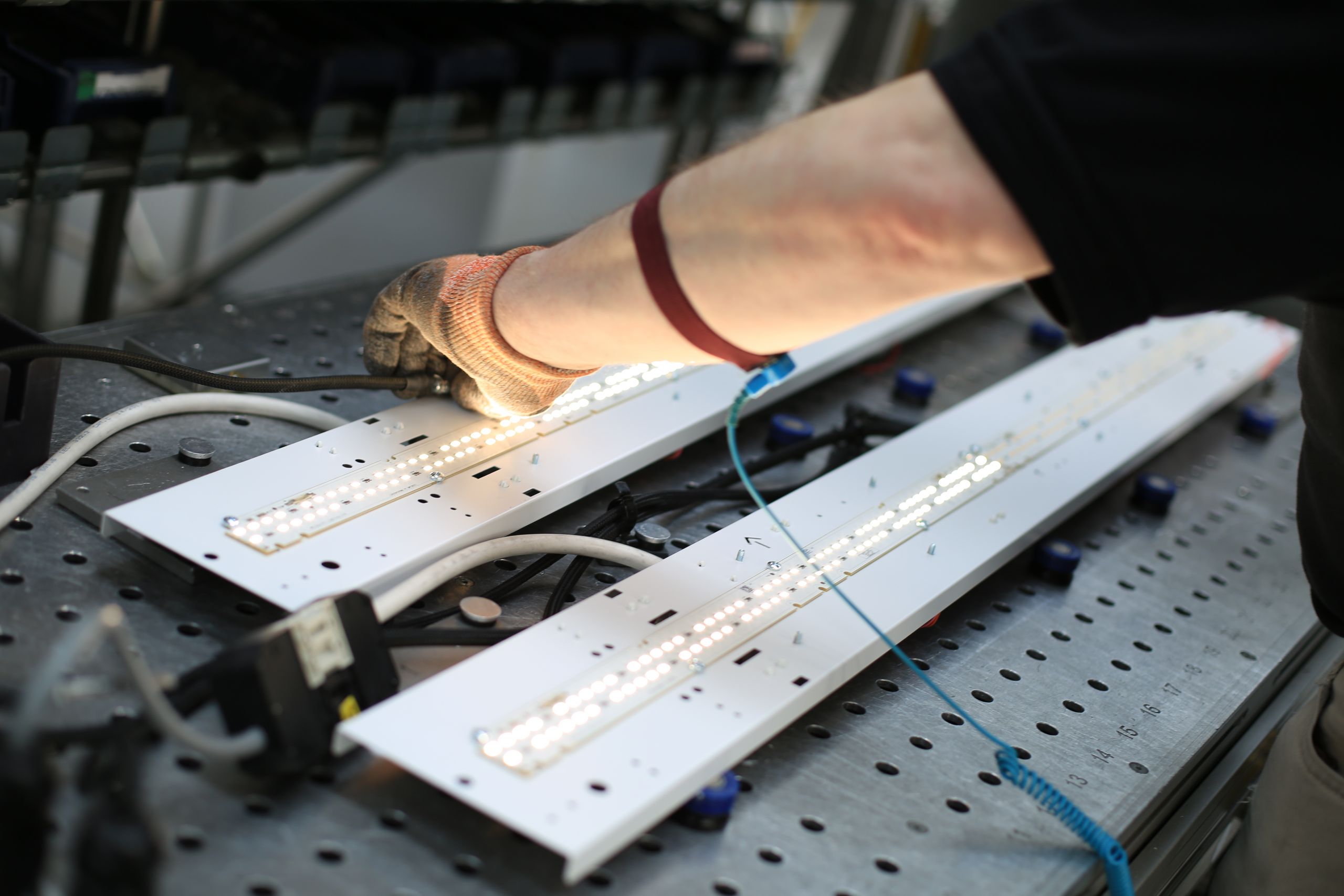

At 18 Circular, we’re taking that on directly, offering Cat A circular lighting as a service. High-quality, track-mounted, UK-made fittings that stay in circulation; installed, retrieved, refurbished, and redeployed. A model that cuts embodied carbon by around 80% compared with business-as-usual, while saving clients upfront capital.

Circularity isn’t just better for the planet. It’s better for business. It reduces risk, smooths budgets, and creates more resilient supply chains.

And it feels like we’ve hit a tipping point. A year ago, hardly anyone had heard of Vinted. Now it’s everywhere; a mainstream example of how fast a circular model can move once it clicks. I can’t help wondering if the next 12 months will bring the same shift in our own industry. Because if it can happen with clothes, why not construction?